This type of technique can be used in the first phase of the generation of the parabolic shape of short focal mirrors or large diameter, the mirror is always and only in the lower position.

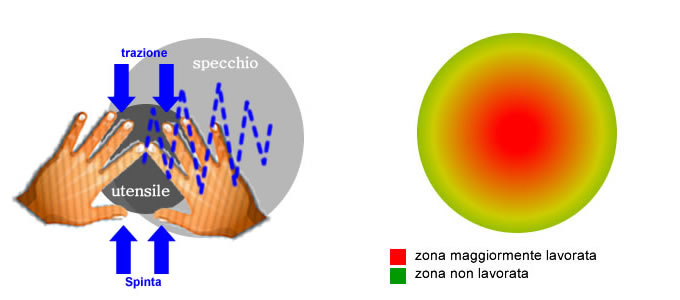

hand position ( for small tools below 15 cm)It is the one with the thumbs pushing a tool edge , while the annular and the average exert traction from the opposite edge. indexes tool support in the central area.

In the case of larger tools you can place your hands as you would in the other central race techniques, always having the foresight to exert thrust and traction acting on the edge and never on the surface.

During the longitudinal movement of the tool-and-fro, It is carried out at the same time a constant transverse displacement , for which the center describes a series of segments of straight line in the shape of "W". The extension of the races is such that the edge of the tool does not go beyond the edge of the mirror in the upper and lower zones in the longitudinal direction, while it is present a small lateral swiveling out, on average less than 1/20 the mirror diameter.

This determines a trend to “W” expanded, with stroke segments increasing in length until mid-lateral displacement and then decreasing stroke segments until it reaches the end of the races on the opposite side.

The operator performs the forward and backward strokes and simultaneously performs a slow and constant rotation around the tool. After some past ( from 10 until 15 ) it makes a rotation of the tool to an arbitrary value ( on average 30- 40 degrees ) in the direction opposite to that operator.

The figure is produced a deepening of the central area with respect to the starting sphere, with performance of the next profile in the ideal parabolic.

SETTING AND ENFORCEMENT

- Position: mirror under, tool above

- Tool: reduced to 50 % diameter mirror , Patina pitch with modified outer zone

- Pressure: no or very weak and localized at the center,

- excursion: trajectory of segmented “W” expansion up to half races and subsequent contraction.

- racing Number: from 5 until 10 , dependent on the mirror diameter, for each series of "W" in a direction.

- times : circa 2 seconds between 'return stroke, time dependent variable to the dried mixture .

- Path: During the races the operator moves around the tool according to a slow and steady rotary motion and rotating the mirror ( 30-40 degrees ) in the opposite direction after an arbitrary value racing. ( normally 10-15 )

- Grane used: the order of microns for abrasive polishing (cerium oxide, iron oxide, alumina and other ...)

- Effectiveness: very good for the purpose of approximation of the parabolic shape, poor in the speed of realization of the same.

- Form produced: deepening at the center of the mirror surface with parabolic trend.

- Precautions: key is the verification or regeneration of the perfect tool operational status before each session ( adaptation, channels, hardness, etc… ).