The machining of a mirror for the telescope provides that a raw glass disk which will constitute the mirror, He is rubbed with its center against the edge of a second glass disc forming tool function, with the interposition of abrasive carborundum wet.

The abrasive used for the heavy initial work roughing or excavation of the curve is very coarse, so that it can work with greater speed and efficiency in the removal of the large amount of glass that will bring the mirror to have a concave spherical surface and, and the tool having the convex complementary surface.

Once that has been achieved the desired depth of the abraded ball cap that way, We must continue working to refine several times roughness, until you get to get back a perfect shiny surface.

Quell'affinamento is obtained by halving several times the size of the grain used gradually previously.

The abrasives used in optical have a particle size (called "grain" or "grit" to the Anglo-Saxon) well defined with reference to the maximum diameter of the grain, and the commodity numbering that identifies it reports the number of meshes per inch square used to achieve that precise separation with a sieve.

Each grain is able to "cut" of the broken glass (by both the mirror from the tool) that for the most part appear to be comparable in size to those of the abrasive, thus leaving the craters on the surface in the processing of roughly size of the grain used (except for almost, or better "accidents" special detachment of the flakes "deaf", ie "peninsulas" of glass that are slow to come off a lot ... and they do it according to the law of Murphy "The moment you can create as much damage as possible" streaking heavily already almost mirror polished).

During the phase of progressive ripening of the surface of a mirror in processing, You must then check the performance of the abrasive grains that we are using, continuing doing the job until a test with a suitable means of magnification, not it is found that the surface is uniformly smooth and free of the most coarse dall'abrasivo products craters previously used.

Only a complete disappearance of those coarse craters, it may be decided to continue the work halving the particle size of the abrasive, preparing the purpose heavy cleaning job.

In this cyclic mode of operation you arrive early to use an abrasive whose average grain size is very small and with it the craters. Then the inspection requires a high magnification that you can no longer get by simply reversing a short focal length eyepiece, as in the old days; but today it is possible with small portable microscopes that are also equipped with a grating that is superimposed on the observed zone and allows to have a direct visual comparison with the asperities observed, compared with the known size given by the grating.

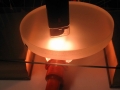

The mirror in question must be placed on a glass shelf, and it must be able to be inspected by illuminating it from below, and also laterally, to give way to grazing light to highlight the craters of transparent glass, that illuminated frontally would not have sufficient contrast to allow them to be identified.

The usable magnification device is a small plastic microscope, It equipped with LED lighting with 2 AA batteries 100 magnifications, It equipped with an eyepiece reticle, with each division 2 hundredths of a millimeter (20 microns).

With this microscope, in practical use they can find within each division of his network, craters with a diameter up to a little more than 5 microns, amply sufficient in order to identify the craters of the finer grain usable before polishing to pitch, which it is the grain 1000 which it has a maximum diameter of grain with 9 microns.