- This topic has 178 replies, 6 voices, and was last updated 3 years, 6 months ago by

Giulio TiberinI .

-

AuthorPosts

-

18 September 2016 at 5:12 #8413

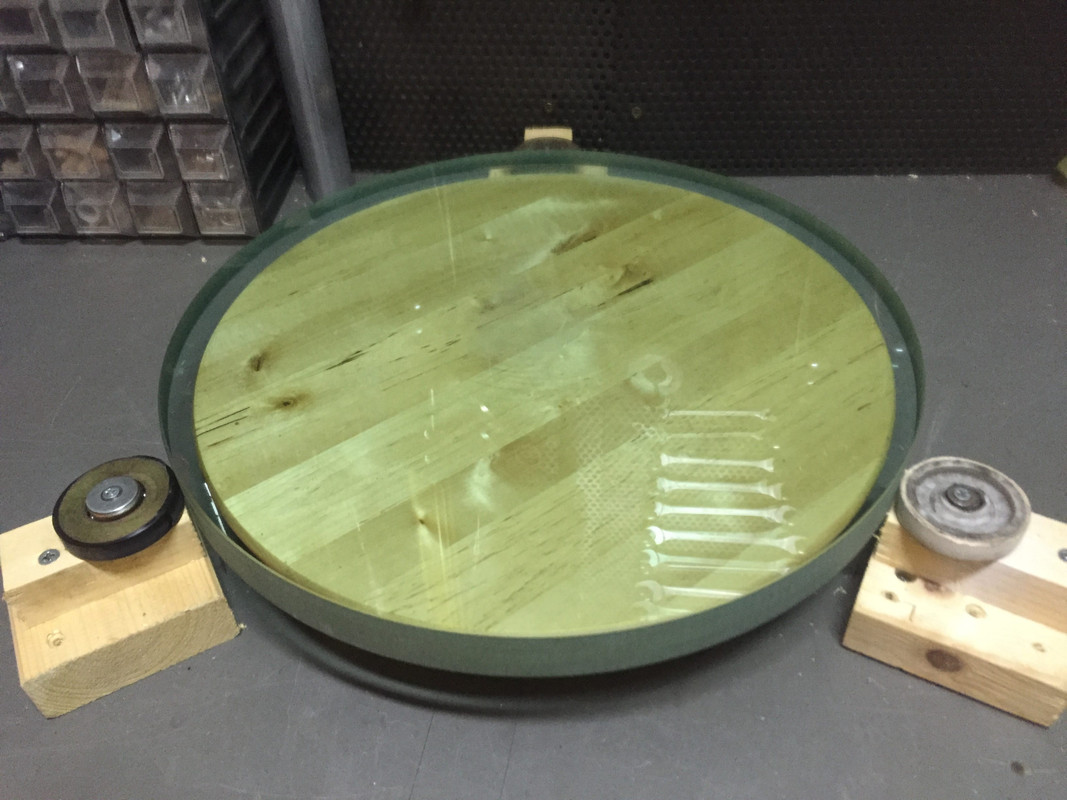

a better picture of my piece of glass placed on the rotating stage that will facilitate my work

…I have completed these days,I owe it to test with the glass moving, of course I have to connect the belt he will turn…begin on Monday, the first scratch

…I have completed these days,I owe it to test with the glass moving, of course I have to connect the belt he will turn…begin on Monday, the first scratch  we'll see how everything evolves!!

we'll see how everything evolves!!

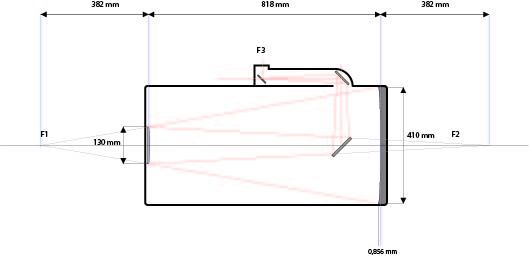

but here my initial project developed with a vector graphics program

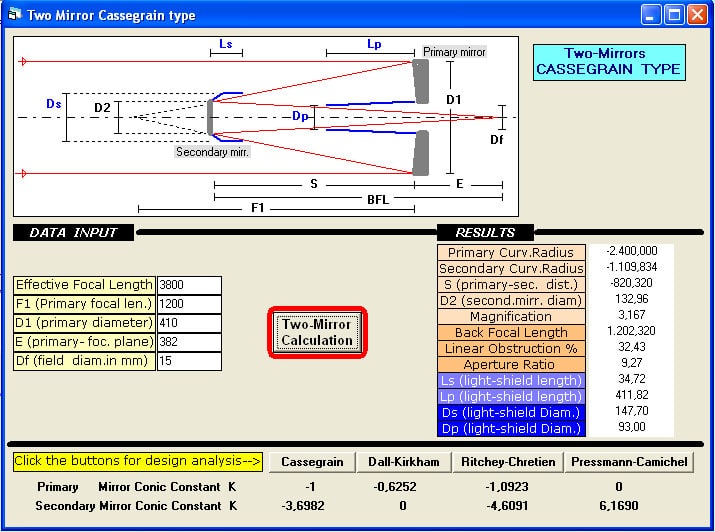

Finally place also elaborated project with ATMOS with different values from which roughly coincide with the actual project

18 September 2016 at 10:16 #8416

18 September 2016 at 10:16 #8416This guy learns quickly !

I do not know how old you are, but you have the enthusiasm ( and also the rush ) Young age, but maybe I'm wrong, I also I stopped being guy for decades, I am rather hasty…

Then Luca, we start from the schema:

-the arrow, as he had already written to you Mirco, and of 8 millimeters ( + Spiccoli ) not of 0,8 It means that there is a lot’ glass to remove

-the tube can not have the same diameter of the mirror, Currency well the dimensions of the pipe, you need to have the correct sizing of the optical path and the back focus.

– all those diagonals are unmanageable, better one, if necessary move it later, in the direction of the secondary. You have enough space to the maximum extent “light shield lenght – LP” ( eventual hood of the primary )

Satisfy my curiosity, why did you decide for the Cassegrain and you're so determined not to consider other solutions ?

18 September 2016 at 15:33 #8418ciao,

So for I again arrow wrong to transcribe…I expressed the extent to mm in the project(I'm 0,856 cm)…I made the same mistake the starting post

then take off the glass I have a lot '…

for the size of the tube maybe in graphic design is unclear cmq I will take it to the end now interests me realize optical (the hardest part)…the other problems I solve them by road

I like to go by degree…

I like to go by degree…

regarding the diagonals if I move to the secondary I find a F3 much longer to accommodate…I inserted to obtain a high final focal length and also to straighten the image(correct me if I'm wrong)….In fact, I aimed at 3600 by calculations made with ATMOS and I managed to get 3800

What alternative solutions could be observed instead of the Cassegrain?

It would be the easiest solution?Thanks!

p.s.

ho 43 years! 18 September 2016 at 16:47 #8419

18 September 2016 at 16:47 #8419Ok is right, proceed step by step, But if you prepare an optical path so divided, It must be studied before , otherwise you can find yourself the optics that are not configured that way…

You can easily move the diagonal and leave one alone , no focal changes

overall, You choose one and remains so, change the size of the diagonal of the fire and the extraction from the tube. It must be calculated according to your project and inserted on Atmos ( parameter “Is”, primary-foc.plane)A solution in my opinion a bit’ easier ( if the intention is to make a Cassegrain “pure”, thus excluding Dk and RC ), is making a primary F4 ( diffice, but less and less of an F3 ), when it is finished you have a parabolic mirror with which to make a great Newton 410 / f4 to spectacular observations. Just add a diagonal plane ( but they do not lack

) and it is ready.

) and it is ready.

At that point you would have plenty of time to devote to the hyperbolic secondary ( even harder Primary ) while you have a telescope now completed also in the mechanics can use, to arrive at the end to have a double-pipe configuration Newton-Cassegrain, ( with perhaps Cassegrain F12 ) just replace only the secondary hyperbolic if necessary in place of the floor and vice versa diagonal, It would be a doubly specialized system , for deep-sky and planetary observation.

) while you have a telescope now completed also in the mechanics can use, to arrive at the end to have a double-pipe configuration Newton-Cassegrain, ( with perhaps Cassegrain F12 ) just replace only the secondary hyperbolic if necessary in place of the floor and vice versa diagonal, It would be a doubly specialized system , for deep-sky and planetary observation.Sorry if I gave you the “boy”, ( I have “solo” 9 more years ) but then so are a bit’ we all grattavetro , at least in spirit, When we embark on these adventures.

19 September 2016 at 0:28 #8420

19 September 2016 at 0:28 #8420The dual configuration a bit attracts me…

Apart from the fact that so the arrow would be reduced by a lot…0,641 cm, About two millimeters less to dig and on the other hand it would immediately provide a system already ready you can use (and I can not wait to try the mirror 41

and on the other hand it would immediately provide a system already ready you can use (and I can not wait to try the mirror 41  )

)

But if I choose this route should drill the pipe in two places and then prepare it for both Newton and for the right Cassegrain?

As far as I could diagonal plan to use that of the current Newton?(Mak 90)Meanwhile, thanks for the idea…surely I will assess your advice ammodo

Tomorrow I give start the ball rolling…I begin to work the glass seen mm to dig!!

See you soon

20 September 2016 at 14:42 #8453

20 September 2016 at 14:42 #8453The dual configuration is a very good tip and a harbinger of great satisfaction that in this case come earlier, e (perhaps) give you the “charge” for the rest of the adventure more complicated (possible) realization of the convex secondary to a further configuration of the Cassegrain family.

With regard to the secondary of a Maksutov (the Mak90 should not be a Newton believe), I think it is never recoverable because it is not flat, and especially because it is unserviceable aluminate directly on the lower face of the closure plate.

But a secondary for a Newton's always good to buy it, and it never costs a figure (see on teleskop express.de).

Certainly you will have to drill the pipe in some choice points (assuming it is a tube and not a more comfortable trellis):

– At the top side, for Newton fire;

– At the bottom behind the center of the mirror in turn drilled, if thou understand using the Cassegrain family version to its focus.

– In low and in a lateral position, if you use a Nasmith fire that saves the primary hole, but forces you to a mirror plane tertiary.24 September 2016 at 15:28 #8494here I am,

Update a little post…therefore, with regard to the mahk90 (I apologize to the forum for mistyped an abbreviation for the telescope

)I meant a Newton 130 mm then that is the one mentioned at the beginning of post…I was wondering if you could reuse seen that the mirror is flat even though I was uncertain in sizes(I see too small)…still well I decide later…Meanwhile, I refer to the link you passed me to recover a possible plane mirror

)I meant a Newton 130 mm then that is the one mentioned at the beginning of post…I was wondering if you could reuse seen that the mirror is flat even though I was uncertain in sizes(I see too small)…still well I decide later…Meanwhile, I refer to the link you passed me to recover a possible plane mirror

thanks Giulio

thanks Giulio

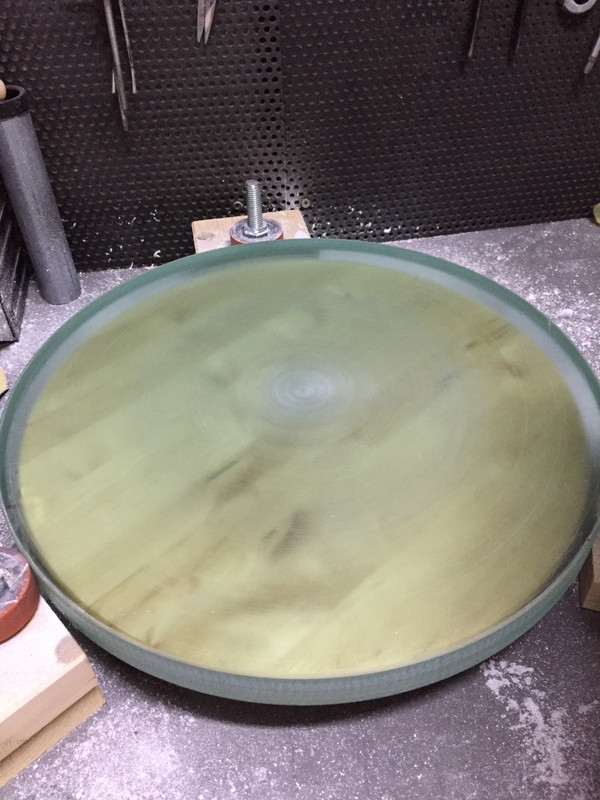

Meanwhile, it shows you the progress of the work of scratch scratch…

these days I managed to recover three bevel sessions to around 1,4 Arrow mm and about 5 hours of abrasion….ask for more experienced if more or less back with the drawn arrow Rates

I seem to dig very slowly(maybe it's just me

I seem to dig very slowly(maybe it's just me  )

)

For now I'm using the grain 40 to work, however, they notice the big scratches on the glass….I hope to smooth them again later with the finer grits

I wondered as part of the arrow using the 40 grit…I had thought up to 5-6mm(Correct me if I'm wrong )

)here is the glass worked with about 1.4mm Arrow…

measurement of the arrow I'm running with a homemade spherometer…I was inspired by the place of Mirko

See you soon!!

24 September 2016 at 16:13 #8497

24 September 2016 at 16:13 #8497Luca Eye ! you have to make a ball, or something like that for the moment, but from what I see looks like you're just digging in the middle, or perhaps is the wet mirror that makes it transparent and does not see whether it was achieved uniformly by processing.

Check if the glass is consumed in the same manner throughout the surface, or if there are still glossy parts.

Do not worry ( currently ) of the times and the amount of processing, concerned about the quality, do things the right way is more important, and is the best way to go “fast” !

24 September 2016 at 16:40 #8501

24 September 2016 at 16:40 #8501How excavations? (That is, in that way keep in touch mirror and tool).

With abrasive the trick is not to put too much, because he would much easier to grind himself instead of attacking the glass.

Is’ ok also put a little water (just a splash of drops) because too much, Working with you throw the abrasive out of the mirror too early, before its abrasive exhaustion, reported from the initial noise reduction.26 September 2016 at 0:52 #8514@Maximum

Arguably the roughly glass is not have a point more dug in the middle than the sides…I'll try to improve in the coming sessions

For sfera no problem…I think I can obtain it just needs time!

@Giulio

I use mainly of the rotating plane using a small tool but also to alternating I passed manual vertical Moving on to W…

26 September 2016 at 15:37 #8516

26 September 2016 at 15:37 #8516Here in Italy “all roads lead to Rome”…but someone comes to us via Beijing-Buenos Aires.

To dig with the rotary plane of the contraindication to the comfort and the efficiency of the excavation in the mirror curve, It is that you have to keep the mirror on the floor (= under) and the tool in hand (= above).

(whereas working hand you have the greater efficiency, albeit with a much longer time, holding the mirror in hand (over it) and rubbing it onto the rim that is on the table, doing become the convex tool and the concave mirror).For the excavation of the curve of the work configuration with the rotary floor would be much more comfortable the use of the "Spinning grinding system" also said fixed pole (fixed post), that you see in the movie that you Gordon Waite “Linko” further on, After a few words of explanation for his acts Gordon:

the turntable you've got it already. To transform it into an efficient machine “Fixed post”, and serve only montargli a mechanical beam to "bridge right- left "with a hole for a post through the crowds in the center. Cross adjustable forward back position straddling the turntable, from which it descends a 25mm idle pin which enters into a metallic glass embedded in the plaster to the tool center.

With that machine also works very hard quartz mirror 500mm diameter movie, coming to dig an arrow to the focal F 4.5… which means digging to a depth of 6,94mm…in 6 hour, of the table with a rotation speed of about 35 – 40 rpm.

As you will see in the movie, Gordon first shows a tool of diameter equal to 75 or vice versa 80% of that of the mirror (the movie mirror diameter is 500mm, and the tool is 400mm);

The first overlaps with the mirror and a plastic ruler measuring the difference in diameter mirror – tool 100mm.

Then pushes the tool to spill over the rear half of that measure 100mm.

Adjusts the upper crosspiece so that the idle pin that puts you, can enter into the glass of the tool center in the precise position in which it has been moved.

He does two laps of adjustment to the machine to close well then the cross latches, and removes the pin (showing never pass on the mirror in hand with the pin)…

Upload the tool 12 kg of gym weights as ballast.

Ri-pushes the tool in its place, He puts the pin and works on the quartz for about one hour for each grain 40 , 60, 80, 120, 220, 320, For a total weight of 6 hour, without interruptions, but only putting teaspoons of abrasive, occasionally spraying a little water, and removing with a sponge sludge processing.

The movie is this:

————————–The "trick" of the fixed-pin machine is due only to the relationship between the tool diameters and the mirror and to the tool decentralization respect to the mirror, whereby, a decentralization below the 50% of the difference value between the diameter mirror and tool, He digs alone in the center; above it digs only to the edge, while at that point of 50% one has the deepening balance of the sphere without changing the radius of curvature.

A little program called “POLSIM.EXE” of processing you find on this page Simulation:

http://martin-cibulski.de/atm/polishing_simulator/But even from a glance over here: https://www.grattavetro.it/forums/topic/ciao-a-tutti/

27 September 2016 at 0:49 #8530hello Giulio,

the video that places me is very interesting but perhaps not as much to do with my rotary table running around 150-200 rpm!(even if I could make a change)That's why I thought of using the sandpaper silicon carbide(use the powder would have been a bad idea given the high speed of the plane),even if it costs a bit more than the powder purchased from Gemmarum :negative:, but it does not matter…what matters for me is to get to the goal…although as you say you will take me more time.

The cross that is made to see in that video I had already planned to finish the job and make the glass a perfect sphere…Then I show you how!!

thank you so much!

27 September 2016 at 18:59 #8533

27 September 2016 at 18:59 #8533

2 October 2016 at 2:58 #8606

2 October 2016 at 2:58 #8606scratching scratching….

So this week I added another three chamfer sessions coming to an arrow 2,7 mm (obviously only the central part) while on the edges I ate about 1 mm for a total of 10,5 hour!

I must say that the work is really hard grattavetro…I did not think that the glass was so hard to consume

…

…I need an opinion on the glass that I'm working…

The guy from whom I bought told me that the glass had been aged for several years, It means that the glass is much stronger?

Being a Pyrex glass you could also heat up to high temperatures without suffering? (80/90 degrees)

2 October 2016 at 15:00 #8613

2 October 2016 at 15:00 #8613hi Luca,

The glass seasoning, for all I know, It does not affect the hardness, rather for seasoned glass means glass "stationary"The curing process provides the time necessary to stabilize the tensions that inevitably will come to internally create the glass during the subsequent cooling at the casting of the slab.

Bedding that, if still ongoing during our work, you can imagine what can cause over time saw the infinitesimal tolerances in the game ...... If I am not talking nonsense ...

If the glass you're talking about was purchased by 'e-bay User near Cremona, person from whom I bought my 260×20 mm and from which I also bought the 'top 410×30 mm, pyrex is not common but now unobtainable calcium-sodium glass in the thickness of 30mm ....

Good luck anyway for your project of undoubted difficulties, but at the same time extremely charming

-

AuthorPosts

- You must be logged in to reply to this topic.