by: Giulio TiberinI

The spectrum of the visible electromagnetic radiation, with the wavelengths expressed in nanometers (millionths of a millimeter)

The realization of a parabolic mirror for the telescope is actually an activity in which the unit of measurement most important and decisive for the quality of the instrument and its performance, and it is expressed in "nm", ie the millionth of a millimeter, equivalent to billionth of a meter.

In the grinding or "scratching glass" operations, the reference number of the most important of all is 0.00000006875 m, that is “for friends” 68.75 nanometers high..

Such is the extent of the "MPE", that is, the MINIMUM "machining tolerance" that can present the reflective surface of a parabolic mirror so that it can be considered “as soon as” good, or entry level, expressing the maximum permissible deviation with respect to the values of the precise theoretical parabola taken as a reference for processing.

But why 68.75, and not another number?

The reason is given by the combination of two phenomena linked to the behavior of the human eye, and to the reflection of a mirror:

THE TWO COMPONENTS LIABLES:

1) The human eye, that has its greater sensitivity in the perception of light yellow-green color liyng in the electromagnetic spectrum of white light, . Spectrum which is known to contain the radiation of all the visible colors "rainbow", from red to violet (see wavelenghts in the above image).

This yellow-green light has a wavelength of 550 nanometers high. (0,55 microns).

2) The reflection that we have for the wavefront of the light coming from the observed object with the telescope, Which front first will contacts (incidence), to the face of the mirror: And if in that contact point on the surface the mirror there are an imperfection with respect to the parable of reference, this would alter the wavefront incident, dommaging it in a value equal to the imperfection encountered.

The same is then immediately reflected wave, and in his passing again on that same imperfection already encountered “in his incomings”, it would be further damaged, for the second time, doubling the amount of the error previously acquired.

Then: An error on the glass creates a double amplitude error in the reflecting wave, and so in telescope vision.

The combination of the two components means that:

Because An error on reflected wave that is equal to one quarter of the yellow-green wavelength , (137.5 nanometers high.) can be detected in the telescope sight…but still acceptable; And sincewe have seen that this error doubles during the reflection: Here it is necessary that the mirror surface is doubly precise, that is at least the eighth of yellow-green wavelenght (68.75 nanometers high.), because in practical use, doubling the error value you will get the famous 137.5 nanometers, or the fourth Lambda (1/8+1/8=1/4, and 68.75 68.75 = 137.5 nanometers high.) that make perceive at the eye the error present, but it is at the "entry level" limit value for the quality of a reflective optics.

Those 68.75 nanometer precision in machining are a very, very small value, but well eye detectable by the simple test of Foucault (that is able to amplify 600 thousand times any error on the reflecting surface).; and yet perfectly accessible and correctable , in the handmade processing .

NOTE: The sensible and curious question that would rise to the assertion that the error what it is “It is visible but still acceptable” is: But what the eye sees through a telescope with such an acceptable error?

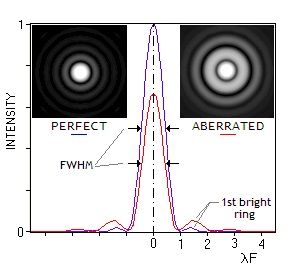

And the answer brings up the wave behavior of light causes, up to an error of the reflecting surface of a quarter of the wavelength (lambda/4), a source point (like a star), high-magnification view with an optical instrument, You will NOT see it as a simple bright dot but you will feel of them one diffraction pattern (see following figure on the left side) formed by a central point that contains the 84% of the light, surrounded by a dark ring and a first clearer outer ring containing the 7% , then by a further dark ring and a second ring still clear outermost containing only the 3% , and so on with other rings always less obvious.

To give an example indicative, a half-wave error (lambda/2, equal to lambda / 4 on the glass) carried by a reflected light wave, It transfers a sensitive part of’ 84% of light contained in the central area of the diffraction notch dot, the first outer bright ring increases so that its illumination, With the result that the telescope sight, the image instead of being punctiform, It will perceive enlarged in a wider stain, which it extends almost to join the central point with the first light ring (see figure above, On the right side) . And it is this enlargement that clearly demonstrates a loosing of "pin-pointing", and a sure loss of contrast , that is, the cancellation of the fine details of objects, that would have been visible at a high magnification, in a more accurate optic..

To give an example indicative, a half-wave error (lambda/2, equal to lambda / 4 on the glass) carried by a reflected light wave, It transfers a sensitive part of’ 84% of light contained in the central area of the diffraction notch dot, the first outer bright ring increases so that its illumination, With the result that the telescope sight, the image instead of being punctiform, It will perceive enlarged in a wider stain, which it extends almost to join the central point with the first light ring (see figure above, On the right side) . And it is this enlargement that clearly demonstrates a loosing of "pin-pointing", and a sure loss of contrast , that is, the cancellation of the fine details of objects, that would have been visible at a high magnification, in a more accurate optic..

Closed NOTE.

MAN VS MACHINE

The following statement would seem a contradiction in our era of widespread and sophisticated automation. But in order to realize a mirrors grinding machine, such precision is necessary to invent this machine "messy" in its repetitiveness, like is messy a man's manual action.

This is curious, but stems from the fact that the realization of a parabolic mirror, for example, diameter 300mm, It is the result of approximatelynear hundred thousand "Past forward – and forth” (..Strokes is "passate" for italians) processing for abrasion of the glass; Each of which removes an infinitesimal part of glass.

Such a long process in terms of time, and very little incisive in unitary glass removal, is more governed by the statistic that not from the precision of a single “stroke” of work.

The amateur astronomer who looks to Do It Yourself, in the first instance is definitely impressed by the amount of manual work in relation of a missor realization, not realizing immediately that those awesome "100000" (strokes) manuals backward and fortward, only then correspond more or less to 28 hours of actual manual labor, (or one hour a day for less than a month).

He is therefore immediately and mistakenly attempting to orient himself towards the realization of a simple machine to shorten a job that is only apparently simple..

But in that case underestimates that a parabolic mirror is not a simple "shaked vegetables"; And the machine that produces a mirror is not a "vegetables mixer", where anyone, simply pressing a button, start the mixer “doing everything by itself”.

It is not technically possible to build or use a machine to complete the complex processing of a decent quality mirror, without previously having traveled and knew very well how to perform that work in MANUAL MODE, accompanied by its inevitable and numerous corrections to be applied to return to that very restricted tolerance of which here you are talking.

In fact, statistically errors of opposite sign committed by man working in a natural way, will self elide them, in a manual processing, acting according to simple rules, that make he remains "more or less" around empirical but resolutory parameters, because TESTED BY TWO CENTURIES of good manual processes.

While an amateur car is not sophisticated or professional, performing thousands of strokes mechanically PRECISES, and "all the same", (that is NOT able to imitate the work within certain "random" limits, of the human work by hand) will only multiply by number the errors in different areas of the mirror, also greatly increasing the severity of certain of them. Where insted manual labor with random strokes would have easily eliminated the one and the other.

It goes without saying that a simple rotating table amateur machine can instead help considerably in the partial phase of the initial hogging a curve and rough grinding of a mirror, which will then be corrected and finished by hand…. AS ONLY BY HAND YOU CAN DO BETTER..

fulvio_

Giulio TiberinI

Giulio TiberinI

Giulio TiberinI

fulvio_

massimar

fulvio_

Giulio TiberinI

Giulio TiberinI

massimar