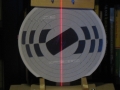

For those looking for ideas to gear up realizing what it takes to lead the Foucault test, I present a gallery of images of my way to work.

The environment must be a room with the temperature as constant as possible, and a length of at least a meter and a half more than twice the focal length of the mirror in question, such that we can install the two mirror supporting tables and testers support, and to allow the operator vision from behind the tester…(or the installation of a webcam).

MIRROR SUPPORT

The mirror in question rests on the inner edge of the lower two horizontal longitudinal members, fixed for all diameters from support. The dimensions of the base and the height of the posterior pole of this model, make it stable up to 400mm diameter (16”).

- The rear vertical post is reinforced by a rear rib.

- On the basis there are three bolts with the function of adjustable feet to ensure alignment of the end mirror reflected toward the Foucault tester, which notoriously is installed parallel to the axis of the mirror, at a distance from it equal to the radius of the sphere generated from the processing Curvature. Distance fact that is worth twice the focal length.

- The three pins are arranged at 120 °, and undertake three threaded inserts "spider" (also named T-nuts) wedged in the lower wall of the base table.

- With heavy mirrors would be preferable that the three legs were real legs having their base of support rubberized, Jointed and independent with respect to the adjusting screw, e (and this is difficult) operable upper from the screw, not from foot. The articulated foot is better than the simple bolt, whose adjusting thrust roundabout directly agent on the table below, easily it translates into an imperceptible but unwanted lateral movement of misalignment, which disturbs the alignment.

- The mirror in question is "sitting" on the two lower longitudinal side members and engaged in the upper part making contact off at the drawstring that is lowered embracing the rear pole, a kind of "collar". Once the horizontal upper crosspiece of wood has fallen in front of the mirror, are screwed by hand the two nuts that the approach to it. Dice must not be tight, but adjusted so that the crossbar “pinches” and latches the mirror account the Couder mask .

FOUCAULT TESTER

It is the type suggested by Texereau page 59 of his well-known ESSENTIAL BOOK: "The construction of amateur telescope", download full free, or chapters, the site that tracks down "googling" such in the web.

- It is a tester with a separate source from the blade, and having the trolley free blade to slide on two runners in metallic plate with slot guide in the shape of inverted "V". The track is a monorail in simple curtain tube for home windows, within which a threaded anchor rod passes to the two end angles.

CART METER

It is weighted with a piece of thick steel plate, and bottom it is held against the pin micrometer with an rubber elastic. The longitudinal displacement takes place with the sole thrust carried out directly by the screw of the micrometer, wherein the contact pin with the carriage ends with a heat-shrinkable sleeve containing a bearing ball diameter 4mm.

- A laser level by masons, which traces a continuous red line multiplex, It helps the tester alignment with the center of the mirror in question. Its fastening to the trolley ballast rectangle is obtained by means of the built-in magnet which is available. Obviously the ballast rectangle is fixed on the carriage perfectly parallel to its longitudinal movement.

THE TESTER KNIFE EDGE

Is a normal razor blade, carried by the carriage, to which, to obtain the desired straightness of the cutting edge, has been "flattened" his sharpening, wiping for a few minutes on a glass surface (with or also without fine abrasive powder.) to eliminate all the microscopic indentations left by the grinding sharpening, It can cause serious problems with the test run with the appearance of many unnecessary diffraction fringes.

- The blade is secured to its vertical support with a single central screw, so that the inclination can be adjusted exactly parallel to the image of the slit reflected by the mirror. The operation is done by putting a magnifying glass even if only of the type "type opener" in the place where it should be put the eye. In that way the slit will materialize on the glass of the lens , and adjusting the blade parallelism will occur, making sure that the entry of the same in the reflection cone of light from the mirror, determines the complete and simultaneous extinction of a whole image of the slit.

THE SOURCE OF THE LIGHT TESTER

employs aeExtra bright blue LED diameter 5mm (…the color is subjective, and to me it seemed that the blue give less noise on my vision), powered by a flat battery 4,5 volts with the interposition of a resistor in series from about 100 ohm.

To avoid introducing errors of assessment in the Foucault test, and then create false corrections that would lead to astigmatism, the light source must be as close as possible to the blade which intercepts the luminous return beam from the mirror, in other words, the light beam which starts from the source and returns on the blade should diverge as little as possible.

Nowadays we are advantaged because there are very bright LEDs that have a diameter of only 5 mm. So the distance between the center and the LED meter blade is surely in less than three centimeters, while before the advent of LED diodes this distance was much greater as it used automotive type lamps, whose bulb is considerably bulkier, as you will be seen from the description contained in the tester book Texereau. the dimensions of the lamp of that time a well-determined distance greater than the minimum possible with the mounting of a LED, but nevertheless still capable of not incurring astigmatism, for focal ratio mirrors F equal to or greater than 5.

To test the lower focal length mirrors, It is no longer indicated the Foucault test, but using amateur test “caustic”

THE SLIT OF THE TESTER

In the optical test it is necessary to make use of point light sources. The point source par excellence is the pinhole, ie a small hole with a diameter of 10 – 50 microns, difficult to achieve in practice.

In addition to the problem of difficult realization, there is the fact that such a small hole passes very little light even if the source was powerful. In the test, however, a mirror need to have sufficient light, why we must ask with the tester to a double evaluation distance of the focal distance of the mirror in question.

For example: for a mirror with diameter 300mm focal ratio F = 5, There should be posed with the tester at a distance of 3 meters, ie equal to the radius of curvature of the central mirror surface. Radius of curvature which in turn is twice the focal distance.

The pinhole is then replaced by a slit whose width is identical to the diameter of the pinhole, with the advantage that the slit of the operation is identical to that of the hole, but the extension of the slit ensures an otherwise impossible with the hole lighting, and also, the slit is very easy to realize, as we shall see here below.

The slit is convenient to install it on an aluminum plate which is inserted and extracted from its seat in the manner of sleigh, with a 5mm diameter hole which will be located facing the LED source.

- The extraction of the plate to slide which carries the slit, fully discover the underlying Led, whose BRIGHT SPOT reflected by the mirror in question, is much better detectable "in the field" at the distance of the tester, (by means of appropriate manual "moving" of a white cardboard sheet, that is mentioned in the caption of an image) to bring it (with coordinated maneuver the legs in the mirror holder, and the same tester) exactly at the point between source and blade, where we will place the eye for the conduct of the test (or a webcam).

- The two edges of the slit can be drawn from two razor blades; or two pieces of 1mm foilstock, caulked and leveled in order to achieve a perfect straightness of the edge (with the same system applied for the knife carriage and any razor blades). The two flaps are then secured to the support plate with double-sided tape / slide, or with screws.

- The adjustment of the opening to 10 microns of the slit is very easy, inserting between the straight edges facing, and before their mounting, a few micron thickness “spacer” It consists of a piece of magnetic tape and VHS videotape, or cassette (internationally known with the term: “"compact cassette"”).

MICROMETRO THE METER

It was recycled by removing and eliminating the headband measure to a standard Palmer with range from zero to 50mm, and using the same original ring which fixed the headband, to secure the screw of the instrument to the angle aluminum header rail of the carriage. The 50mm range is more than enough to bring down inside, easy, the extension of the longitudinal displacement of the carriage necessary for the execution of the test of any amateur mirror of diameter equal to or less than 600mmF3.8, vue that the total draw of a similar mirror amounts to only 17,83 mm against 50 mm available).

GALLERY OF IMAGES