My biggest Dobsonian is a 14 "F5 in homebuilt 2003 following the directions of the note "Bible" by Kriege / Berry "The Dobsonian telescope" with unobtainable constructive shares in the book tables, but I have inferred in relationship proportional to the diameter of the primary, with obvious transformation from Anglo-Saxon measures in metric measurements.

The result was an exceptional instrument, sturdy, docile and stable, the ground part of which (roker box+ mirror box + contrappesi..ecc) can weigh around 28kg.

Far too many for me to move it by hand only, although having equipped it with handles.

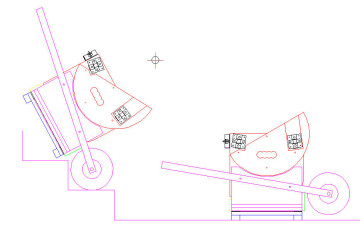

The best and most practical was (but it still is) “no cart”, but the direct conversion of the base of the telescope in BARROW, so you can move equally, I just, insecurity, excluding unnecessary physical effort. But especially only to add the FEWEST possible HARDWARE, WITHOUT changing the eyepiece height from the ground.

This is because the "minimalist thought"It is a fundamental part of my mentality, He considers the very near perfection to a brilliant and functional conceptual simplicity, which, however,, gives you the only certainty that, for any technical solution devised by you, There will be sooner or later, a simpler and better functioning of your, devised by someone else, making rightly passed your busy "brain storming".

I console myself so, because this kind of only certainty “negative”, is the engine of true progress, and it's (at the bottom) the some spirit very much more important of the scientific principle, that works always in that way .

The "Barrowage" (intended like transforming in wheelbarrow), is still the optimal solution, and in my case it happened following the procedures suggested by the "Bible" mentioned.

My requirement was, however, to realize a wheelbarrow with the transport functional handles, While remaining short as it can be easily fitted on the telescope (in the transport, ready for the discharge operation) inside the boot of my car Ford Fiesta (or in the boot of my van-camping-car, that I use for stargazing on mountains),

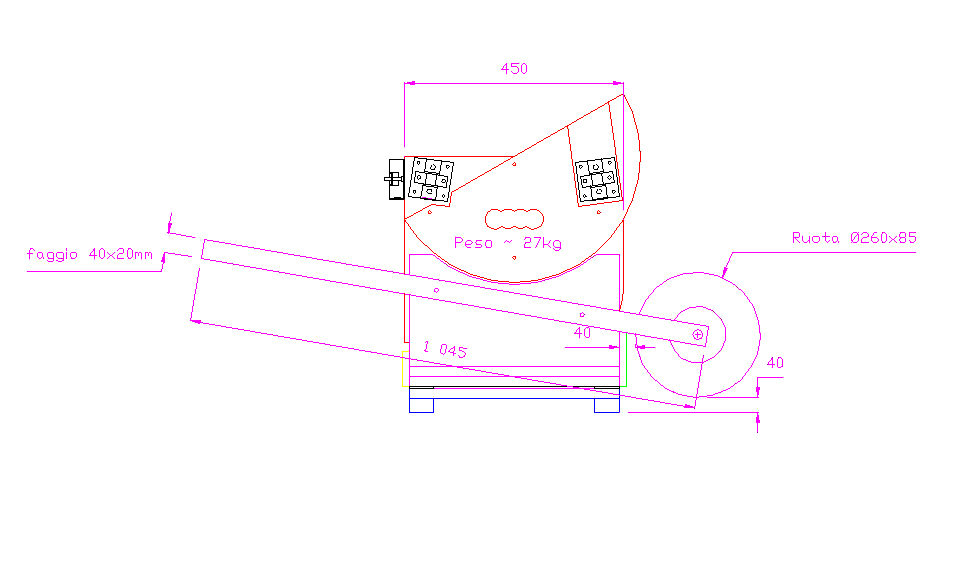

For this I built the Poles BARROW only long 2,4 times the width of the rocker box, or 104cm, in beech wood 4x2cm rectangle.

Moreover, I wanted to experiment with the construction if, using wheels of a diameter 5 standard cm greater than the lift of 20 cm, average measure of steps in domestic buildings, it was possible (always maneuvering alone) go up or down the steps stair of my balcony, without having to resort to the use of bulky three-wheeled carts that the guides normally accompanying "stairlift", but they would be incompatible with the dimensions of the luggage compartments of my means of transport.

About this, given the high inclination of the wheelbarrow base “carriolata” of the telescope necessary to overcome steps both to go up or down stairs, and for moving with the wheelbarrow on the observation field with the telescope fully assembled, it is necessary to prevent the primary mirror case, to exit from its internal location to the external case, to which the wheelbarrow shafts are installed, in order to fix the two boxes together, making them a single body integral with the base of the telescope on which the wheelbarrow shafts are fixed.

To do this, simply drill a hole between the two boxes, placing a spider insert on the internal one, so that you can insert a bolt from the outside which, manually screwed a few turns to the internal insert, ensure that impediment by acting as a union between the two boxes like a bolt pin.

Wheel sizing and its distances from the Dobsonian body, experienced to get past the steps standard construction, with “step height” 19 ±2 cm, e “Fedt! 31±2cm

The choice fell on two pneumatic wheels (but work best also those non-pneumatic, that is “full”) Chinese Ø250x80mm, from 8 Euro each. in DIY centers, with the seat in the hub in red plastic without bearing.

The mounting of the wheel at the end of the bar in beech, It was done on a cantilever threaded bar M12mm with self blocking centring nuts, to stop a piece of steel as tube sliding bushing in contact between internal threaded hub and wheel plastic bushing (so that the latter did not rotate directly on the thread of the M12 bar, but on the flat surface greased the tube / bushing interposed).

The two M8 threaded pins, for the connection of each side with the Rocker box , were made using four screws of "Fisher brand" screw anchors for concrete SLM/8 type (see figure in the gallery of images following), type eyelet, Put yourself in the poles in two through holes, and fixed in a very loose and such as to allow their free hand rotation (making comfortable grip on the eyelet) , albeit with some possible inclination to facilitate the entrance.

That slack fixing has been obtained by screwing on the thread a kind of low self-locking nut , and leaving some play to allow the Fisher pin the free rotation/inclination necessary for the’ screwing the rocker box.

The nut has been housed in a suitable location set within in the bar with a drill bit diameter 20 mm to sleep comfortably and disappearing this nut, and accept the socket wrench for adjusting his mechanic game (gap).

In the wall of the box Roker, They have been inserted four threaded inserts M8 female, of the type for mounting mechanical forcing (…They are screwed into the wood where they remain blocked):

You see “T-nuts”, also known as “pal-nuts”;

Even here can go equally well other common bushings “metal tube”, internally threaded to accept a bolt M6 or M8, and externally equipped with a cutting helix which is screwed and hangs stably in the wood, simply by screwing up at the bottom of their mounting bolt (M6 M8), and then screwing it all (more bolt bushing), forcibly into the through hole already drilled in the wood, with a diameter equal to the exterior of the insert tube, measured excluding the boss of his external anchor screw.

The Insert screwed once forcibly until it disappear unter the level of the wood surface, remains perennialy in that position also by unscrewing the bolt used ti fit it.

Two pads for pole, ensure a useful contact bearing stanga-rocker box, without damage to the parts.

Outside of these personal desires, I applied the rule known to maintain the wheel is about 40mm from the ground at rest with the telescope, and an identical distance of the wheel from the primary case, as reported by Kriege & berry book & Berry, and as summarized in a CAD figure inserted in the following gallery of images.

Gallery using some creative helps better understand the set:

The functional result of the ascent and descent stairs was very satisfactory, and these also show two of my movies: