Work characteristics - Aggregates - granulometric Sequences - Traceability of abrasives to achieve mirrors for telescopes.

CHARACTERISTICS OF WORK:

As already mentioned in other articles relating to the construction of mirrors for telescopes, current amatorial making of such an object provides a raw disc of glass that go to constitute the mirror, is rubbed with his center against the the edge of a second glass disc acting as a tool, with the interposition of abrasive powder and wet, which will bring the contact areas to be consumed, with the mirror that will assume a concave spherical surface and, then countersunk in parabolic shape in the final stages of processing; while the tool surface will assume the convex shape complementary.

CHARACTERISTICS OF ABRASIVE:

Those powders are then fellow of the "glass scratcher trip", up to completion of his work. They are made of very hard materials with sharp and cuttigs edges, that for pressure contact shatter and grind the glass in crumbs with average size comparable to the size of their grain , or their "grit" (both terms are equivalent to the anglo american term “Grit” -).

HAZARD’ PROCESSING:

The abrasives supplier must put at the disposal of the safety data sheets and use of all materials and products sold. But potentially greater danger of whole machining, remains to inhale the glass in the form of silica at the molecular level.

But from the technical point of view, all stages of the processing must be carried out “wet”. It should be known so that if this happens in reality, It has avoided any possibility of the glass inhalation, and consequently the processing, as it is done for centuries, produce no hazard problems.

NAME AND DIMENSIONS:

Each abrasive is characterized by a number of grit, that expresses the number of meshes per square inch of the sieve used for obtaining its precise separation by different particle size. Also if today in reality, this is true only for the coarser grits, ranging from 16 to the 220.

Beyond the grain 220, that is from 240 to the 3000, many companies no longer use sieves, but they operate the separation for "elutriation", ie sedimentation of the powders in water. Where the size of the powders further granule, settle before others. For example, the powder mean diameter 100 micron sediment and 1 minute, while the powder with average grain 16 micron sediment and un'ora: Then take the first name (for example) of emery 1 ', while the second Emery 60 '.

NOTE: Modern technology makes us forget that, also in not so ancient times, intelligence overcome completely to it. And the lack of commercial availability of an abrasive refined in wel refined and guaranteed particle size , It was filled by “prehistoric” sedimentation process, that allowed (and still it allows) to soak a certain amount of abrasive ground, and after waiting for the time needed (possibly throwing away the coarse deposits obtained up to that moment), to obtain from then on, a perfectly fine grain size sedimented (using machinery, how they could already get the cavemen). END OF NOTE

The habit of professional jargon in the industry is very hard to change, and then, although it is perhaps more useful and easy to understand by calling an abrasive with its average grain diameter, BUT you are still using different encodings that needs necessary tables of equivalence between various grits and its true average sizes, -.

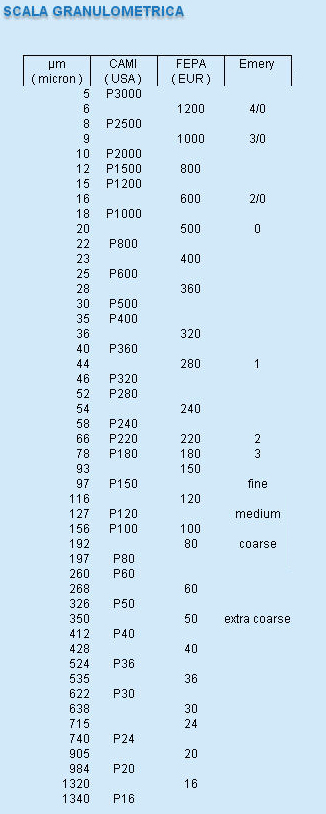

Table of equivalences with abrasive particle sizes in microns

The types of abrasive used in the processing of the mirrors are:

- The silicon carbide called universally Carborundum;

- The fused aluminum oxide (In Italy named "Corindone") (but also it takes the name of Garnet, o Smeriglio o Emery (in French));

- The industrial diamond;

- The oxide of zirconium;

- The oxide Cerium;

- The iron oxide.

Making telescope mirrors means to use abrasive powder in decreasing grain size from the initial stages to final processing.

The work usually starts with the laborious hogging or excavating the curve, which takes place using very coarse grits, such as 60 for medium to large mirrors (medium grain 268 microns, then about 2.5 tenths of a mm); or grit 80 for working mirrors from small to medium size (medium grain 192 microns, ( that means 2 scarce tenths of a mm) so that the excavation proceeds with greater speed and efficiency in the removal of the large amount of glass.

Once is reached the depth named "arrow" in the shell of the desired sphere abraded in that way, We must continue working with different sessions, in each of which uses a progressively abrasive grain with about half size compared to the previous, up to refine the surface shiny again getting it perfectly polished.

The change of grain takes place as soon as, to a careful examination of the surface being machined, (Maybe using means of magnification), the current Abrasives have erased any trace of rough asperity left by the previous grain.

TYPES OF ABRASIVE AND EMPLOYMENT

SILICON CARBIDE: It's a Ceramic material “extraterrestrial” with hardness 9 the Mohs scale.

The Mohs hardness scale start goig back from hardness 10 Diamond, which it is the absolute maximum hardness of any material.

A hardness 9 It is thus only second to diamond.

The definition of Extraterrestrial material is due to the fact that we now know the SiC to be very common in interstellar space and in meteorites, product because of the nearby of red giant stars, that synthesize the carbon in large quantities by a process of nucleosinthetic union of three helium atoms.

"On Earth" in its natural state is very rare, but it is artificially produced by 1893 (discoverer American society "Carborundum") using sand and coke coal in electric furnaces with graphite resistance to temperatures of 2500° c, in the vicinity of which it forms Carbide crystal pure green silicon, that away from the electrodes crystallizes in pure form less and less abrasive changing color in black. It 'sold in bulk in bags 25 kg with particle sizes from 24 to the 1500 while its retail sale in Italy is not easy to find.

- USE: It is the most widely used abrasive (personally) in all phases of realization of the spherical surface of the mirrors: From the initial roughing, with the grits so much coarser than the larger the mirror to achieve, at the refinement “Satined surface” with the grit 800 (I never used the grain 1000 and I never had any problems of roughness in polishing).

FUSED ALUMINIUM OXIDE, synonymous with corundum (or Emery, -, or Garnet): It 'a ceramic material with hardness 8 the Mohs scale. Its grits are normally finest, that start from 180 with his 78 micron mean diameter, and arrive at 1200 with 6 microns, but usually in the processing of mirrors of using to the maximum the W6 which has a diameter 14 microns and is virtually equivalent to the grain 800. their identification is criminally “criptics” with single-digit numbers that say nothing, preceded by a letter W; or simply by the number of minutes of sedimentation.

- USE: Today this kind of abrasive used is less of a past time, and then they are also very hard to find. They were (and still they are) recommended because less aggressive of the carborundum, and then it was easier to obtain a less rough surface in the machining operations, as in those manuals, however, at the price of a much greater processing time.

Frankly and insider, I think that today with manual processing (that already does not have the aggressiveness of the work with a machine) there is no practical difference in the perfect gloss (of course obtainable with the usual pitch and cerium or zirconium oxides), on mirrors worked until the grit 800 in carborundum, or machined to the equivalent (for the grain size) W6 grit aluminum oxide.

INDUSTRIAL DIAMOND : is pure carbon, having hardness 10 the Mohs scale, that is the hardest known material.

In the manufacture of amateur mirrors it is not used in powder form but can sometimes be profitably used for the excavation of the curve on simple machines with rotary table, in the form of tools cup or encrusted disc galvanically of industrial diamond powder.

CERIUM OXIDE: It 'a white rosy powder with grain around the micron, (There is also the rarest namedOPALINE, that is cerium oxide powder further refined). Both are used in the phases of polishing and subsequent parabolization of the mirror surface from the “satinated” left from the grit 800 del Rats. Is’ no more used for simple interposition between the two glass disks (mirror and tool) with mixed water,, but with a tool covered by a layer of squares of pitch that must have only “partially yield” as a result of frictional heating given by processing.

This partial collapse of the pitch, and fouling in it dell 'cerium oxide, together with the presence of a little water and find the optimum working temperature (that is normally achieved after at least half an hour of tool strokes), are the essential ingredients to produce on the glass surface of the mirror, no longer just abrasion, but abrasion accompanied by a "transport" molecular clearly visible under a microscope glass (Like craters rounding edges, that prevoiusly where chipped, up to their disappearance), which glass back locally fluid (at molecular level), for the heat-friction of the pitch and the other components, it go literally filling the craters and to pave the microscopic surface roughness, creating a super glossy like the surface of the water when it is pierced by sunlight incident rays, without making spurious reflections at the point of that incidence.

Polished that are unobtainable when abrasives (while infinitely small grain, and in the absence of his capture from a medium like the pitch), They can roll freely between the tool and mirror surfaces.

ZIRCONIUM OXIDE: E 'used in dentistry and orthopedics to fabricate prostheses (false teeths, coxe femur etc.). Reduced to a fine powder, thanks to its cubic molecular structure (similar to that of diamond) It is hard, and therefore fragile but abrasive in its ceramic fragments with sharp edges (because its have ends with sharp edges “at molecular level”).

Personally I've used it for hand machining my mirror 300F6, but I have not noticed differences with cerium oxide. Rather…: Cerium at a certain point of the machining creates autonomuosly beneficial foam water, able to very efficiently circulate the abrasive, and create that already named “molecular transport” wanted. The foam with zirconium oxide is not done independently, but must be caused by adding a bit of dishwashing liquid in water processing. But his biggest flaw remains is the lack of availability and with it the higher price than the cerium.

IRON OXIDE(or also oxalate of iron) : The first is called “Rouge” - “-” or the American slang “Rouge”. Abrasives that are "poor" in the sense of a much more common in past time, that they are less exotic than Cerium or Zirconium, therefore since the mid '800 widespread, and perhaps initially only used abrasives. Their lower abrasiveness forced to a longer and more accurate processing, also providing excellent gloss surfaces.

The big problem It have, and that has determined his abandonment, is that it get dirty of rust anything with which they come in contact. And this is serious because there is no way to clean dirty of rust in tissues and many furnishings .

GRITS SEQUENCE OF USE

The sequence is designed to refine the mirror surface with the progressive decrease of the abrasive grit dimensions. Then it is driven by halve the previous average grain size in microns, indicated in the tables of equivalence (Figure 1).

Obviously the halve sequence is determined by the starting grit size, to get always and at least to end grit 800.

The halving is not peremptory, but is the method that provides the best performance, and because it makes it easy to see under a lens or microscope the disappearance of craters left over from previous coarse grits. Disappearance indicating that it is time to change grit.

But any grit in the vicinity of half the value of the preceeding grit, may be fine. At most only elongates work times, Since changing from a coarse grit to a too fine grit will require more Time to get rid of the big asperities.

An example of a sequence may be as follows

| Carborundum | 60 | 80 | 120 | 180 | 240 | 400 | 800 | Cerium Oxide |

| Ø Micron | 268 | 192 | 116 | 78 | 54 | 23 | 12 | 1- 1.5 |

In the middle of the indicated values exists throughout the following series of other grits, that can replace one or more entries, depending on availability of the sales provider per minute.

| grit size | 100 | 150 | 220 | 280 | 320 | 360 | 500 | 600 | 1000 | 1200 |

| Ø Micron | 156 | 93 | 66 | 44 | 36 | 28 | 20 | 16 | 9 | 6 |

Quantityes '

Quantities of abbrasives are depending from the diameter of the mirror you want to make, and from the way of work of those who use, and so it is not easy to indicate of reliable.

The mistake that we make more easily and frequently, is to use too much abrasive in each wet, in the intention of increase the efficiency of the excavation, but instead with so, optaining the practical opposite effect, to force this abrasive to “grind” himself in large quantities, and very less grind the glass, and with that, we hardly increase the working time and the costs in abrasive, limiting hardly the glass grinded, instead of speeding our work., and so wasting unnecessarily abrasive in his inactive self-destruction .

For the determination of the quantity, until recently (i.e. before to make inconvenient ' DIY small mirrors, come to our markets low-priced Chinese mirrors) you could peek at the catalogs of European suppliers, reading the composition of the abrasive kit for optical autocostruzione for sale. And perhaps what you can still do today, If from these suppliers someone is surviving (but the commercial dying has been great).

Carry data from a European manufacturer that closed a few years ago.

| mirror diameter | Gives 230 until 250 mm | Gives 290 until 350 mm |

Gives 360 until 400 mm |

|

Stone Cote for chamfering |

N°1 | N°1 |

N°1 |

|

ROUGHING Carbo 60 |

1.5 Kg | 1.5 Kg |

2 Kg |

|

ROUGHING Carbo 80 |

1 Kg | 1.5 Kg |

2 Kg |

|

Running or "wedding" Curves (equalization male and female) carbo 120 |

500 g | 500g |

1 Kg |

|

Carbo 180 (Emery W240 ) |

500 g | 500g |

1 Kg |

|

Refining Carbo 240 (Emery W240) |

250g | 350g |

500g |

|

Carbo 400 |

150g | 250g |

400g |

|

Carbo 800 (Emery W6) |

100g | 100g |

100g |

|

Carbo 1000 (Emery W8) |

50g | 50g |

100g |

|

Polishing Wood pitch Gulgoz #64 |

1 Kg | 1 kg |

2 kg |

|

Cerium oxide |

150g | 150g |

250g |

|

Opaline (Cerium oxide fine) |

100g | 150g |

150g |

Carry here in the sequence that I have personally used in the processing of my 250F5.

After the successful completion of that mirror diameter, Having found good, I continued to use the same sequence of too abrasive for subsequent jobs. The realization of the 250F5 started from a blank pre-hogged by machine from the supplier Reginato, and thus it excludes the use of coarse grains of that phase of work.

The following are the recordings on my "journal of glass scratcher" concerning the manufacture of the 250F5 except parabolizzation that lasted almost as, with different "game over" ( returning back towards the sphere), with a cerium oxide consumption of about 200 g.

| Carbo | 120 | 180 | 320 | 500 | 800 |

| Consumed | 0 | 71 g | 82 g | 25 g | 29 g |

| N ° dried | 0 | 70 | 85 | 28 | 28 |

| Average abrasive consumption for all types of grain | ~ 1 gram to each wet |

| Total wets | 211 |

| Duration of each wet in minute | 3 |

Total minutes of my hand work = 633 like a 10.55 hour(and about 633 laps around the work table).

At the rate of two strokes per second (1 stroke forward 1 stroke back) add up 75960 strokes manually performed (but the term stroke sometime is translate like "racing" from the ignoring automatic translator) …75960 is a good number! But your biceps are thankings instead of complaining !

REPERIBILITY’: for badinage, but in truth we can say that in Italy these days we have a large amount of each type of …”"grane"” …(in the sense of the italian corresponding term “troubles”), very different from the type abrasives. These latter, however,, unlike the first, are desirable goods, but very rare (in Italy) , species such as retail sale.

Retailers suppliers (there is a minimum retail trade in Italy, but is directed to processing of jevelery precious stones) They are to be found in the network by typing in the search entries, for example “Sfaccettatrici for precious stones”or vice versa “precious stones cutting machines”; And within sites that sell those cars, are well consumables used by them, that are “polishing powders” or Cerium oxide or aluminum for sfaccettatrici; while for the cutting machines it comes to powders “silicon carbide”.

One of these companies is called Italian Gemmarum Lapidator .

New suppliers in Europe appear and disappear depending on the strength of the global crisis that engulfs, and usually only sell these abrasives purchasing a glass kit “blank” to work. A recent company that also sells separately is the French optique OAMS astronomique.

Some pictures: