The next step in the design phase and determination of the appropriate position of the various baffles along the optical path, It consists in the realization of real shielding elements.

As it said until now, It is particularly easy to apply to your telescope, if the study for the positioning of the baffles has been made in a phase of preliminary design, ie before you have physically built the telescope, or if it has to do with a telescope intubated instead of a Dobsonian.

While achieving improved a telescope already built, We must take account of imitations and the constraints imposed by the property and the existing solutions.

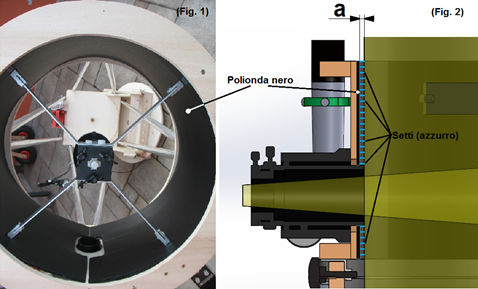

For example, in most Dobsonian telescopes scratchbuilt, the secondary cell, It is internally coated with a black plastic sheet (generally thin corrugated material), as in one of the photo below (fig. 1).

Since this surface appears to be very close to the edge of the field of view (fig. 2), it is difficult schermarne the reflected or diffused light, as the parameter "a" (seen in previous articles), It turns out to be very small, which would require a large number of baffles (in azzurro in fig.2), little pronounced and very close together, This is not easy to achieve.

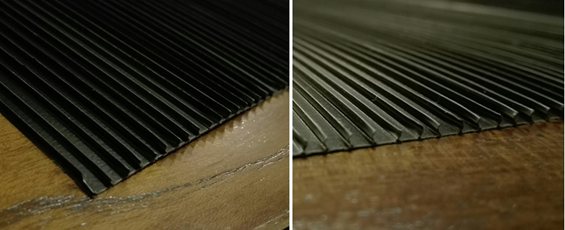

not easy, but not impossible, in fact an inexpensive solution, It is to be able to remove one of the two outer layers of the rolled polionda, so as to sguarnire inner ribs. To do this, just insert between the tips of the scissors, one by one the internal ribs, and proceed with the cut, obtaining a result similar to the one shown in the picture below.

In this way, are unable to obtain a sheet with applied over a series of ribs, very thin, little pronounced in height and adequately tight for the purpose. just now, paste this sheet over to black corrugated material already present in the telescope, to obtain the sequence of baffles necessary to reject the first true reflection the primary mirror.

In the file below you you can see some comparisons, between the effect of reflection of a light mail frontally, by the standards poilionda, whose smooth and glossy surface refers to the observer largely the reflection of the incident light, and with the discoveries of the corrugated ribs which instead are able to intercept the incident light, only projecting the shadow towards the observer.

SEPTA IN FOCUSER

Realize and adequately position the baffles inside the focuser barrel is not a simple thing, especially if you want to build an easily applicable and removable solution in case of need.

One option, probably the easiest for those who may have, It is to print through a 3D printer object that is designed, already in its final form, which it can be inserted and pulled at will from the back of the barrel, just as it does from the front with the eyepieces.

In this way it is possible to think of a piece with similar characteristics to the one below.

from design:

At the definition of the concept:

At the definition of the concept:

At the finished prototype:

At the finished prototype:

Or you can cut a variety of pipe pieces, the correct diameter and length, on which to apply in the middle of a series of plastic disperses in such a way as to obtain a tower formed from: piece of pipe, diskette, piece of pipe, floppy disk, etc., gluing it all together(as pictured in the top left, among the above images).

SEPTA IN MAIN PIPE

The baffles to be positioned along the main tube of the telescope, They can also be large, in relation to the optical diameter, which makes difficult the realization of pieces of these dimensions, that are beyond, adequately for, but not excessively rigid to flex at each minimum stress.

As also mentioned in the preceding article, the septum itself, It could also be made of a certain thickness, provided that he then chamfer the inside edge making it thin and "sharpened". Use a thick material, therefore it allows to obtain very rigid septa, however, to the detriment of a greater weight, which when multiplied by the total number of baffles required and considering that will be applied in positions well away from the rotation center of the cradles, It could result in the onset of instability of the telescope problems, which must be rebalanced by adding weights on the other end, or modifying part of the structure.

Taking into account these limitations, the solutions may be, or cut the annuli of the baffles from the aluminum plates, wood, plastics etc., or realizing them by cutting and gluing together several strips of resin impregnated glass fiber fabric (seven fiberglass).

The solution with the fiberglass allows to realize baffles edged, ie with an edge on the entire perimeter, that in addition to giving structural rigidity, They will serve as a basis on which to apply glue or screws to attach them inside of the telescope tube, or to attack the fabric or the black fabric that will act as a tube in a Dobsonian Telescope.

In this case, you will have to sew the black fabric so as to form a tube, having a suitable diameter, inside of which will be applied to the various baffles, and which will then be attached to the box by a part of the primary, and the secondary cell on the other, remaining within the tube structure, Fig.1 (differing from the usual solution which foresees a black cloth hood, to apply all 'around, externally, Fig.2).

HOOD TOP

As for the hood to be applied on top of the telescope, one of the solutions may be as follows:

REFERENCE for a base of plywood circular crown from 7-8 mm thick and the outer top septum made of fiberglass, connected by 4 aluminum tubes, and externally coated with an elastic black fabric.

The black fabric was deliberately chosen elastic, because 4 aluminum tubes were not fixed rigidly to the ends, but they are held in place by rubber bands that run internally.

In this way it was possible to realize a structure collapsible, self-explanatory and compact to use completed.

In the lower part of the wooden base, Moreover, They have been set 4 buttons, that will go to easily engage their 4 complementary, seats on the top of the secondary cell, making it simple and fast assembly and disassembly of the hood.