The pitch tool is an indispensable tool for polishing and parabolizing an a mirror telescope and is therefore useful to have a practical guide that tries to illustrate how to proceed to achieve it.

First, it is good to have in mind all the steps necessary for its creation so as to proceed smoothly with the work, because once you start the process, you will not have much time to recover any steps forgotten.

The tool is constituted by 2 basic elements, a circular support, usually made of plywood or dental plaster and the dough in pitch.

First thing of all to do, is prepare, a container of water at a temperature as close as possible to the air of the room where you are working (It is therefore appropriate to prepare this vessel the day before in order to enable him to get to thermal equilibrium with the environment).

Another preliminary step is the realization of the support which should have a diameter appropriate depending on the type of processing that will be carried out (processing with sub-diameter or full diameter) and a stiffness such as not to deform during the adaptation phase of the patina or during processing (use plywood of adequate thickness in relation to the tool diameter).

Then you will have to cut a strip of cardboard, cardboard or other material having a length a little longer than the circumference of the support and height pariah the thick support, plus 3-4 cm. This cardboard strip will go well wrapped and secured along the circumference of the support so as to realize the banks to contain inside the pitch at the time of casting.

At this point you need to prepare the ingredients for the dough:

- Rosin or Greek pitch

- linseed oil

- cera d'fire

- turpentine

The pure rosin, It has a melting point of about 120-130 ° C and is too hard for optical processing. Then at the rosin are added other ingredients such as linseed oil, beeswax or turpentine to reduce the melting temperature of the dough and make the right hardness.

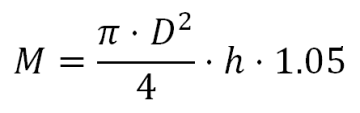

As regards the amount of rosin to be used you can make a approximate count of this type:

Where:

M is the amount of rosin to be used in grams

D is the tool dimetro in cm

h is the average height of the layer of the pitch above the tool in cm (1-1,5 cm are the norm)

1,05 is the density of the rosin in g/cm³

While the amount of linseed oil and beeswax depend heavily on the temperature of the working environment and must be such as to make the dough of the right hardness. There is no exact recipe for these quantities, you go more for experience or trials, although a good starting point may be had by analyzing the data present in this post: Test of the pitch hardness

It is not necessary to start with absolutely exact quantities, as you will be able to modify subsequently the mixture prior to casting on the tool.

MELTING AND CASTING THE PITCH:

To proceed at this stage, It is necessary to have a small pot (big enough to pitch to melt), a spoon to mix (a metallic spoon is ideal) and a heat source. Ideal would be an electric hotplate with thermostat because at the fusion of rosin there are emitted vapors that are flammable, and that could catch fire if they came in contact with the flames of a gas burner (that does not mean those gas must not be used, but with them you have to keep a greater attention). In any case it is always recommended to carry out the work in a well ventilated area.

It starts pouring the Rosin inside the Pan and placing it above the stove over low heat. Rosin will begin to merge as a bit 'at a time. Stir frequently and pay close ATTENTION pitch that never comes to a boil otherwise its properties degrade rapidly. From my experience almost always happens that while the pitch pieces you still have to dissolve the remaining dough that has already melted instead begins to boil. If this happens to you remove the pan from the heat and continue to stir with the spoon. Meanwhile, the heat stored from the bottom of the pot will continue, however, to dissolve the rest of the pitch. Once the boil will be attenuated you will again replace the pot on the stove.

In the next picture you can see that in this case the pitch has come to the point it begin to boil and it is therefore appropriate to take it off the stove.

While in this, you can see that, after mixing thoroughly, the boil has been declining. Small bubbles that you see are air bubbles that were trapped between the flakes of rosin at the beginning of the merger and that does not represent a big problem because it will disappear during the process .

When the pitch will be completely melted, you can add linseed oil and wax previously prepared bees, stirring well to homogenize the mixture.

At this point you have to take a bit 'of pitch from the pot with a spoon and dip it in the bowl with water prepared the day before. Shake well to speed cooling until, once you reach the water temperature, it will be possible to test the hardness of the dough obtained through the nail test (or other methods).

If the test found that the pitch is too hard or too soft will add inside the pot more amount of linseed oil or beeswax or a few drops of turpentine if the dough is too hard, or other else rosin if the dough is too soft.

Once the hardness of the mix meets our expectations we will remove the pan from the stove and will proceed to the casting of the pitch on the tool, not before it had mixed for a few minutes the whole, in order to standardize the dough and get rid of any kind of air bubble trapped.

(in the following video it is shown the phase of the pitch casting for the realization of 3 sub-diameter tools. These are placed on a shelf that is located on an electronic scale to be able to assign to each of the right amount of material)

Now the dough into pitch will wrap evenly over the support, creating a nice flat surface devoid of bubbles or impurities. Otherwise immediately detonate the larger bubbles and remove any impurities.

The following photo refers to the situation just after the casting. You see immediately how the surface is smooth and beautiful reflective consequence of the absence of bubbles or impurities.

After leaving to cool all for 40-50 minutes you can already proceed to take the spherical surface at the pitch.

To do this you must protecting the mirror surface by stretching over a sheet of tissue paper, wetting it slightly in order to improve the contact. At this point leave the tool above the mirror and put on top of the weights until the pitch bend is perfectly adapted to the mirror surface.

Later, after 40-50 minutes from the pouring tar has not yet fully hardened, but still it is very malleable, and then this operation will be relatively easy. If the mixture is allowed to cool until the following day pitch will be much less malleable it will be necessary to soften it or heating it with a hair dryer or by immersing it in warm water.

The last thing to do is to create channels on the surface of the pitch that are absolutely necessary for correct operation of the tool, so as to form the blocks of approximately 2-3 cm side.

These channels can be realized in various ways:

can be created for example by pressing upon a flat bar of metal, or by using an electric soldering (or directly with the tip, or by applying the tip of a sheet metal folded to U to be used as a "spoon" to engrave the surface) with which particular part of the pitch to form the channel grid (P.S: Never coincide with the Centre of the Central block with the tool Center), or by using a silicone grid or plastic on which the tool is pressed (see video below).

To create the micro facet instead, just put a grid or a piece of mosquito net between the mirror and the tool so that the wires that create the mosquito net is rotated 45° more or less than the directions of channels.

The casting of the pitch can also follow other procedures, like for example that creates "candy" of pitch that once solidified must be glued onto support automatically creating channels between an anchor and the other. This procedure is well described in the article written by Giulio and which you can find at the following link: Tool with "candy" pitch

CHANGING THE PATINA

In some machining, especially in those with tools subdiametro it is necessary to modify the shape of the patina making them assume a star shape in order to obtain more nuanced abrasive action toward the edge.

In the following video it is shown one of many methods that can be used to achieve this result while also generating the micro facet.

This has been achieved by interposing between the pitch and mirror a card stock with the shape of the star and a piece of mosquito net.

The tool is now finished and ready for polishing or parabolizing.

N:B: Always remember to run a good fit between pitch and mirror before each work session.

Depending on the type of processing to be undertaken, you may have the need to build a set of tools of different diameters, such as is shown in the following photos.