Forum Replies Created

-

AuthorPosts

-

hello John,

Secondary cage finished and painted

Secondary cage finished and painted… Secondary cage finished and painted.

Secondary cage finished and painted, Secondary cage finished and painted, Secondary cage finished and painted, Secondary cage finished and painted?hello John,

I had already read other witnesses as well, After weeks of reading.

After weeks of reading, After weeks of reading, even though I didn't take the time to properly learn how to perform data reduction.

even though I didn't take the time to properly learn how to perform data reduction.

even though I didn't take the time to properly learn how to perform data reduction, even though I didn't take the time to properly learn how to perform data reduction. even though I didn't take the time to properly learn how to perform data reduction.

even though I didn't take the time to properly learn how to perform data reduction, even though I didn't take the time to properly learn how to perform data reduction:

http://rohr.aiax.de/Using%20a%20Bath%20-%20EN.pdf

http://gr5.org/bath/bathanalysisv2.5.pdfP:S: even though I didn't take the time to properly learn how to perform data reduction. even though I didn't take the time to properly learn how to perform data reduction. So if you use the interferometer, So if you use the interferometer.

Hello and see you soon

Mirco

hello John,

In this weekend then I will open a discussion dedicated to the most demanding work I have done so far which includes all the years of study and practice that I have dedicated to carbon fiber since it is a completely composed instrument with it..

In this weekend then I will open a discussion dedicated to the most demanding work I have done so far which includes all the years of study and practice that I have dedicated to carbon fiber since it is a completely composed instrument with it..

See you soon

MircoWow Massimo, beautiful picture…The surface looks nice smooth and even

complimentoniiiii, you're doing a great job

complimentoniiiii, you're doing a great job

Hi Alberto,

happy to re-read you here in the blog and congratulations for the new dad

First of all, I am attaching the links to three articles written by Giulio and Enrico present here on the site, all referring to the construction and use of the ronchi / foucault tester.

I try to answer point by point:

1) the sites that report the use of old incandescent bulbs is because they are a bit dated, nowadays it is usual to use simple green LEDs (They don't even need to be particularly bright).

2)Personally in the ronchi test I place the crack (made with two fine sharpened penknife blades) in front of the source and the grating only in front of the eye or the camera (obviously with the lines parallel to the crack).

3)The laser pointer for collimation is not essential, for example I don't use it. Then, first of all, you need to position yourself with the light source approximately in the center of curvature of the mirror or twice the focal length. After that, if the light source is placed just to the left of the optical axis of the mirror, the reflected light will end up just to the right of the optical axis, if you put it just under the reflection it will end as soon as sora, and so on. The important thing is to keep the distance between the light source and the return beam as low as possible, 1-2 cm at the most (obviously the returning light beam must pass through the ronchi grating). For the foucault, on the other hand, a blade that half covers it must be placed before the LED. The blade itself should protrude a couple of centimeters above the LED. The light returning from the mirror must be intercepted by this source part of the blades. This ensures parallelism between the source blade and the test blade.

4)I personally prefer the source below and the lattice just above. In this way, I minimize the introduction of astigmatism in the test as much as possible.That said, I agree with the procedure you have decided to undertake, apart with the dot 1 in which you say not to put the slit in front of the LED. That crack is crucial. In principle, the ideal width of the slit should be of the order of magnitude of the spacing of the lines in the ronchi lattice (generally 50-150 microns of bene).

I hope I was helpful…See you soon

Ciaooo

Hello Franco,

Congratulations on your accomplishment

A couple of observations:

1) you absolutely must start adding water during processing, breaks down dust in the air, lubricates the surfaces and distributes the abrasive more evenly.

2) If you can, try to limit the jerkiness of the eccentric during rotation. Surely spraying water between the glasses can help minimize clicks, or decrease the weight added above, or finally decrease a little the play that there are between the various components of the arms.

3) Looking at the eye in my opinion the overflow you are using is a bit excessive, I would not want you to generate an incorrect figure. But anyway, for excavation, I would suggest you use another technique.

4) As already suggested by Giulio, I would move on to processing “Fixed Post” it is a tried and tested technique and it works well (I'm telling you because I used it too). mirror under, tool al 70/80% the diameter of the mirror, and overflow around the 20-25% the tool diameter. Rotation speed of the rotating table even a little more sustained, without exaggerating and if you want, you can use a slight right / left movement of the tool (10-15 mm) to avoid that the edge of the tool always passes in the same place above the mirror (Although with coarse grits you can very well use the “fixed post” pure). In my opinion this way you should feel good about it. let us know

Ciao

Good luck and see you soon

Mirco

Heilaaaaaaa what a nice job that is coming out

Very Massimo

I am in complete agreement with the method of proceeding you have chosen for parabolization. On such a thin and fast mirror, I too would have chosen to work towards the center.

A big good luck, for the continuation.

I stay tuned

Ehilààààà Massimo,

what a job you are doing

You can see that there is a lot of method in your work and the results are starting to show…considering mostly, the size and small thickness of the glass…

Really good

See you soon

Mirco

Hello Carlo

welcome to the blog from me too.

Also according to me a 300 f5 is the ideal choice, as a first realization. Adequately complicated to learn and deal with the main construction difficulties, but still manageable and with not excessive construction times.

As for machine making, a couple of notes:

1) I agree with Massimo, in saying that mastering manual processing is very important in the first place, as it is possible to understand how the various processing techniques modify the surface of the mirror in a different way.

2) Having said that, I do not deny that I too would be for machining , especially for the roughing and polishing phase, these phases are very long and in my opinion boring. The phase in which you really need to have the ability to generate an excellent mirror then, parabolization remains, this phase that I find very complicated to manage exclusively by machine. that, if the parabolization must be done by hand, however, it is necessary first to have acquired the necessary mastery of the techniques. In short, I would not start from scratch with machining, but I wouldn't be super good at hand crafting either, if the final intention is to focus on machining, which is totally different.That said, if you have the technical skills to build a car, I won't say no, also because already only a rotating table (possibly with rotation speed regulator) it can also be very useful in manual processing alone.

I see you don't lack knowledge of electronics, if you need it, I can give you some tips on mechanics. I don't know if it serves a real three completely independent trees, maybe even just enough 1 and then transmit the motion by means of pulleys.I don't think you need the electronic line at the moment, unless you want to know the focal length of the mirror with micron accuracy (useless thing I would say), if ever you just need a linear encoder of about twenty centimeters max, enough to cover the range of motion of the tester (in that range yes, you may need measurement accuracy).

Lastly, I wouldn't focus on the crack at the moment, it could be an upgrade to do in the second place, you will see that even if only with a well-made fixed slit, you'll have a great time and you won't need anything more complicated.

Hello and see you soon

MircoHi Michele,

Yes, of course, the cell must be checked at all angles, however, it was so evident that the thickness was not adequate even only aimed at the zenith, that I have not continued further.

Cell a 27 points can definitely help, but I always find it hard to keep it in shape as you tilt it (I always talk about 25 mm eh).

Hi Michele, good continuation, I look curious, the various updates and the progress of the work

Ciao

MircoHi Michele

Machine roughing, I've always done it with a sub diameter tool, usually 60-70% of the diameter of the mirror and never with the tool at full diameter.

As for the choice of blank, just do two simple simulations to understand that a 25mm mirror is NOT rigid enough.

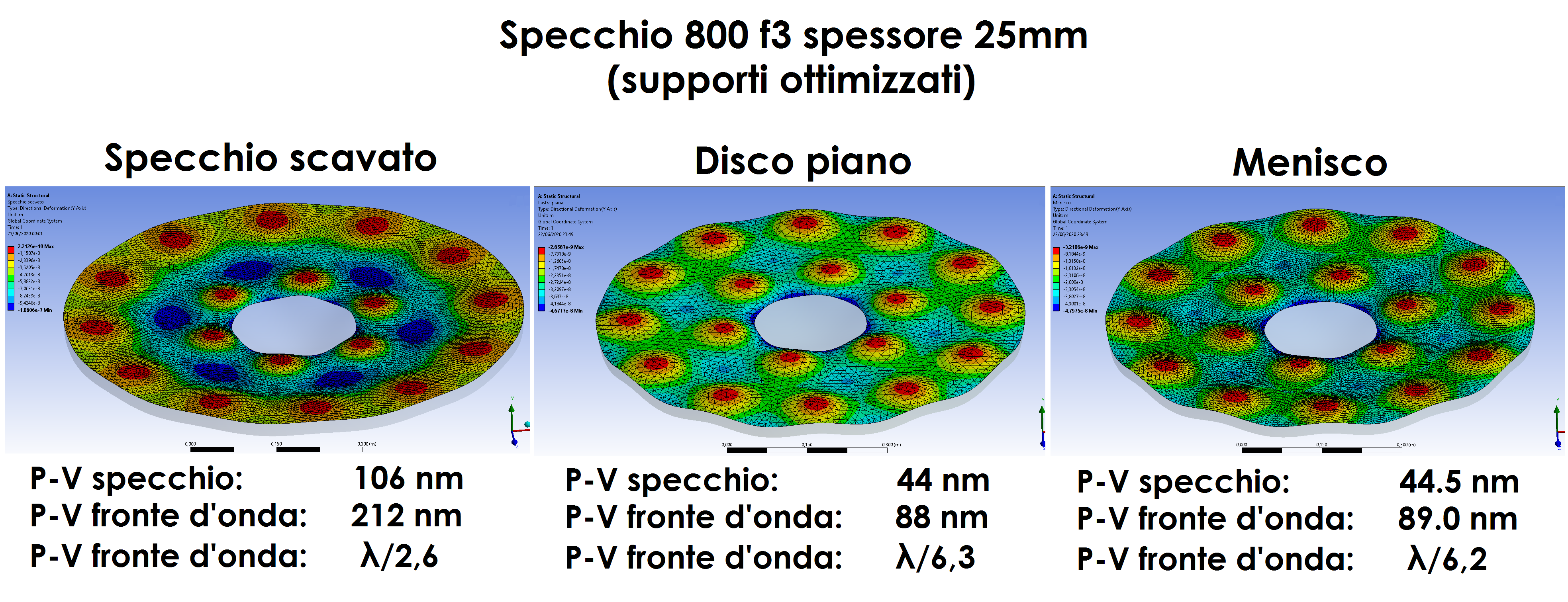

In the attached image I report 3 different cases compared:

the first with a mirror carved in a conventional way, blank da 800mm f3 spessore 25mm

The second with a flat disc, always 800mm in diameter and 25mm thick

The third with a meniscus always 800mm in diameter f3 25mm thick.

The conventional solution gives you a P-V error on the wave front of 212nm

only of deformation due to its own weight.

only of deformation due to its own weight.

The other two solutions also give absolutely unacceptable deformation values for an astronomical mirror, which makes it obvious, that 25mm thick is too small a thickness for this diameter (with cell a 18 support points, if you go up with the number of supports, I don't know what happens, but certainly the cell gets complicated a lot).

Another information that shows this simulation, is that a flat disc and a meniscus, they have substantially the same stiffness and show the same deformations under the pressure of gravity, which is to be expected given the small curvature of the meniscus with respect to the flat disc.A piece of advice I can give you instead, is to contact Schott directly, which can sell you an entire sheet of borosilicate (the slab is large eh, if I remember correctly, like 1200mmx3000mm), thicknesses from 35 at 53mm it seems to me, I go to memory, a cira 3000 euri. If you find anyone else interested, you can have various discs cut to waterjet, and then divide the expense.

Ciao

Mirco

Hi Michele,

I had not set a precise descent curve and unfortunately we did not acquire the temperature data, simply once the high temperature maintenance is finished, we turned off the oven and let it cool down naturally all weekend. The following Monday we opened the oven and removed the blank.I had experimented with polarized light, slight tensions were noticed precisely at the edge of the mirror, but I was unable to quantify them. In hindsight it would have been appropriate to have him make an annealing cycle.

The residual stresses are proportional to the cooling rate and the thermal expansion coeff, therefore with the same cooling curve, in a pyrex blak one should be generated 1/3 tensions compared to one in calcium sodium. In fact, if I ever have to make another attempt, I would try to do it in pyrex.

Meniscus and structure had been generated in a single batch, and the pieces of the support structure in contact with the meniscus, they had been precut so as to take into account the curvature of the same.

I had already seen the link, but thanks for giving it back to me, I had missed it. The arrangement of the support ribs they had chosen didn't convince me at all, so I redesigned them according to other reasons and the result is that shown in the previous pages.

You already have something specific in mind for your project? do you have any idea?

See you soon

Ciao

MircoHi Michele,

However, I remain skeptical about the possibility of building an aluminum mirror. I am aware of several mirrors made of aluminum, many of them mounted on satellites, but on terrestrial optical telescopes, I think there are very few, and those that exist either for particular applications or are experimental.

In almost all the sites I have visited, those who produce and sell aluminum mirrors, propose them for X-ray telescopes, for cryogenic applications, of interferometry, per medical imaging, per laser, IR and more, but for optics of telescopes in the visible, I find practically nothing (this also in the pages you linked).

That said, I'm always ready to change my mind, and like you, I am following with interest the tests that the Brazilians are carrying out, we'll see

hello

Hi Michele,

Being able to use aluminum as a blank is something that would please anyone. Its low price, possibility to mechanically remove material from the back of the mirror to lighten it, low weight etc. etc.. Unfortunately, however, there are some limiting factors that are so important that practically very few aluminum mirrors exist. The only ones I know of (in the frequencies of the optician) they are the mirrors of some satellite chambers for terrestrial observation, but they have crazy temperature controls, which keep the entire optical bench within a range of one tenth of a degree centigrade or some experimentation by ESO and the like, who are able to achieve satisfactory results but with processing techniques that go well beyond the reach of an amateur.

There are problems due to both the excessive thermal expansion coefficient, both to the fact that as Giulio says, it is not at all easy to obtain a degree of polishing suitable for an optical telescope and a thousand other problems, low temperature creep etc. etc.…

Maybe for small mirrors it could also be fine, but I still have doubts about it. In any case, I will follow the CN discussion with interest.

Hello and thanks

Mirco

Hi Michele,

thank you!!

I also believe that this technique has potential, even though I have never been able to fully verify it. The drawback is that there is really a lot of work behind to obtain such a blank.

But the worm of blank lightweight always blends in my head, and sooner or later I hope to have time to try again.

Ciao

Mirco

-

AuthorPosts